Battery Test & Automation Solution

Brand

16CH Battery Cell Simulator Model 87001

- Operating mode: CC/CP

- Channel power: 25W, Channel voltage: 5V, Channel current: 5A (parallelable)

- Bidirectional power supply design

- 480-cell battery pack voltage simulation ability (connected in series)

Battery Module Welding Check ATS Model 8700

- Inspects BMS functions

- Inspects open circuit voltage (OCV), DC resistance (DCIR)

- Inspects consistency of string battery cells

Battery Pack Function ATS Model 8720

- BMS Function Test, Battery (failure) Simulator

- It is for testing the function of battery pack in the production line.

- Inspect battery module performance.

Battery Pack Integrated Testbed Model 8610

- Support via ASAM XIL and ASAM XIL-MA

- Extensive modular hardware

- Support CAN, CAN FD, and LIN communication interfaces

- Independent PLC real-time monitoring

16CH Battery Cell Simulator Model 87001

- Operating mode: CC/CP

- Channel power: 25W, Channel voltage: 5V, Channel current: 5A (parallelable)

- Bidirectional power supply design

- 480-cell battery pack voltage simulation ability (connected in series)

Regenerative Battery Pack Test System Model 17040

- Voltage range: 60~1000V, Current range : 0~750A, Power range : 0~300kW

- Accuracy current / voltage measurement (±0.05%FS / ±0.02%FS)

- Multiple voltage / current ranges for auto ranging function

- Conforms to international standards for battery testing: IEC, ISO, UL, and GB/T, etc

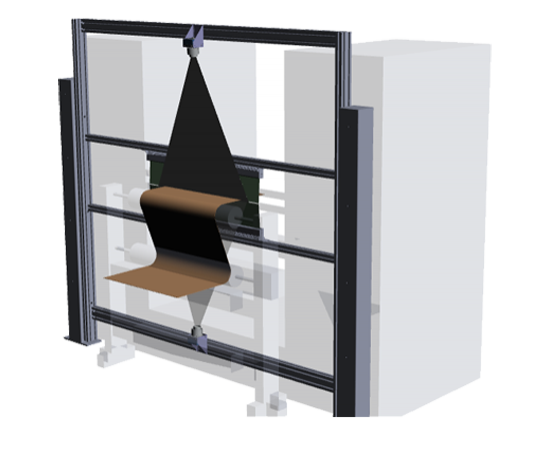

Inline AOI system Model 7505-02

- For ITO (Indium Tin Oxide)Thin-film, RFID and FPC Roll to Roll process online real-time automatic optical inspection

- Equipped with high resolution line scan camera, has capabilities of detecting defects, like bubbles, scratches and so on.

- Use multi-line camera to acquire

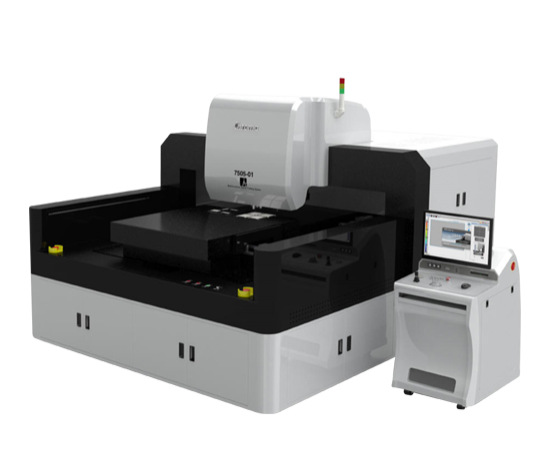

Multi-Functional Optical Profiling System Model 7505-01

- 1D, 2D and 3D measurement capabilities

- Equipped with film measurement function (1D) to do non-destructive film thickness measurement when

Inline Printing Quality Automated Optical Inspection System Model 7505-K009

Applies to Roll to Roll processing and on-line quality control