Description

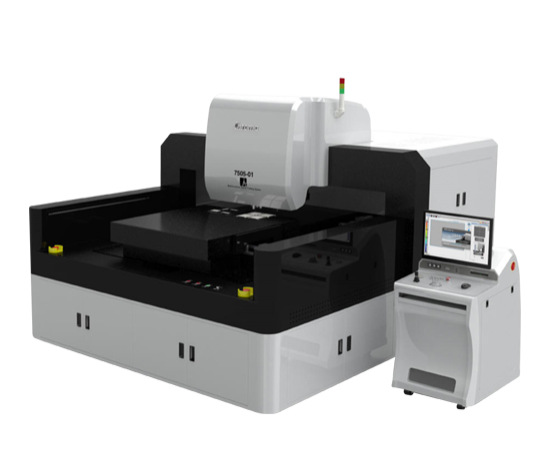

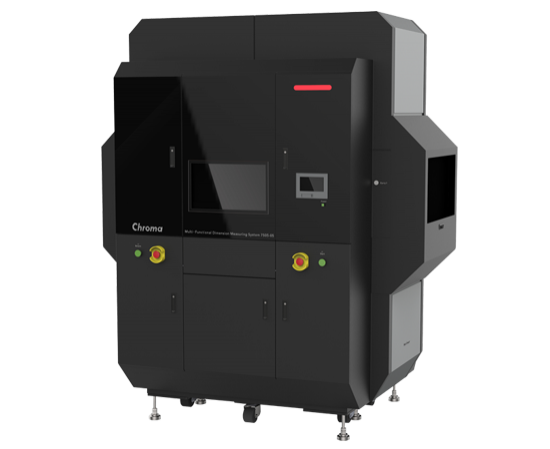

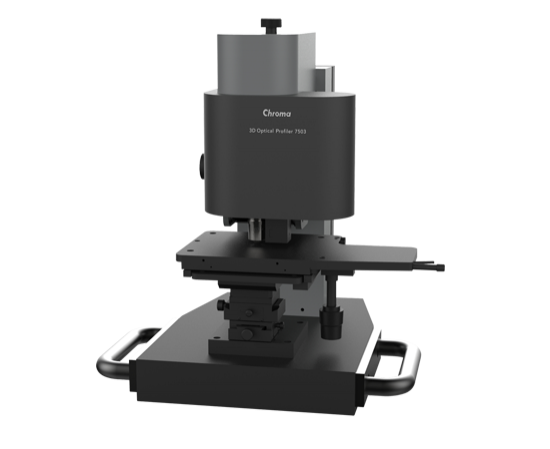

Chroma 7505-01 is the newest multi-function optical inspection system that equips with the capability of measuring 1D, 2D and 3D at the same time. Penetrating reflection measurement is used for 1D film thickness measurement to measure the non-destructive film thickness on transparent and translucent material. The 2D measurement can perform horizontal scan using High-resolution line scan camera and computer controlled platform with measurement range up to 700mm x 900mm. In the mean time, the stage has vacuum suction capability that can suck the soft display such as touch panel, e-paper and AMOLED to form a flat plane. This system is applicable for various micro nano level and large scale measurements. The 2D defect measurement is able to detect the flaws of bubbles, scratches and foreign objects. The 3D measurement function can analyze the height and depth of 2D defects which was not available in the traditional 2D inspection.

The 3C products nowadays is towards compact size and the associated upstream industries like semiconductor, flat panel, flat display, PCB, soft display, e-paper, OLED, Micro Electro Mechanical Systems (MEMS) and electronic package are requesting smaller 2D/3D measurement size. The accuracy of each measurement size can reflect the product quality and performance, thus the requirements of monitoring the product size and quality during manufacturing is increasing. Chroma 7505-01 is able to provide micro nano level 1D, 2D, 3D multifunctional measurements to satisfy the needs of each industry and research unit, which is the best selection for improving efficiency and saving cost.