Description

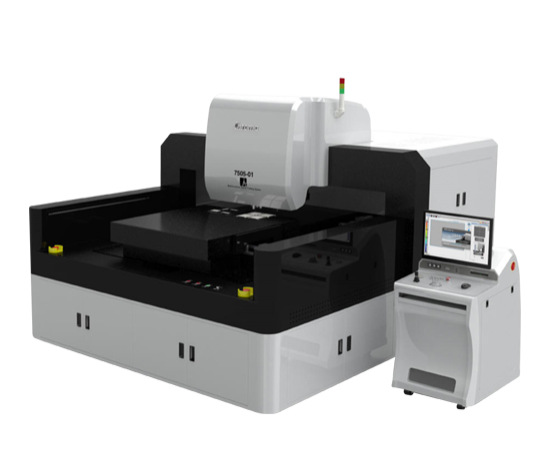

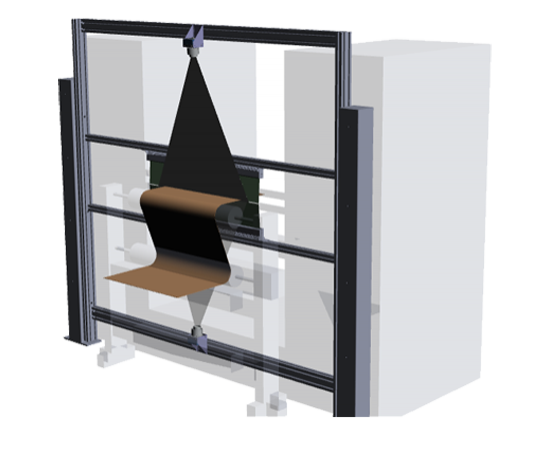

The 7505-02 Automated Optical Inspection System is integrated with high speed camera to shoot Roll to Roll manufacturing processes of ITO (Indium Tin Oxide) film, RFID and FPC that is Line-scan Image Inspection System with PC-based structure.

The 7505-02 applied visual inspection core technologies like high sensitivity line scan, Line-scan camera, low-aberration distortion lens, high brightness lighting and high speed frame grabber. It reaches uninterrupted inspection with high speed and 2D surface defect analysis through real-time synchronous trigger frame grab coordinated with defect detection judgment in high speed and accurate memory control technology as well.

The problem found in the earlier manufacturing process for saving the more cost, reducing the fee of scrap and rework and increasing gross margin percentage. For the consideration of salary increasing, Automated Optical Inspection (AOI) assists manual inspection to be the tendency of nowadays industry development. Chroma 7505-02 is a Image Inspection System specially for detecting soft material or defect on the film that can replace partly labor

Chroma 7505-02 is designed to be a detection station for the uninterrupted entire manufacturing process. Use the existed CAD files for comparison that flow rate of entire manufacturing process will be up to3mper minute. Update CAD file synchronous to meet the development of customer product following various product specifications of manufacturing processes.