Description

Recent advancement in optical inspection technology continues to find its path into a variety of market applications. Innovative automated optical testing has become essential and indispensable in areas such as effective dimensional measurement to ensure product manufacturability and process control.

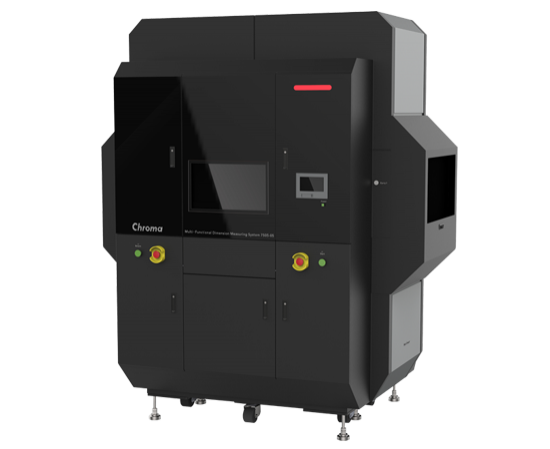

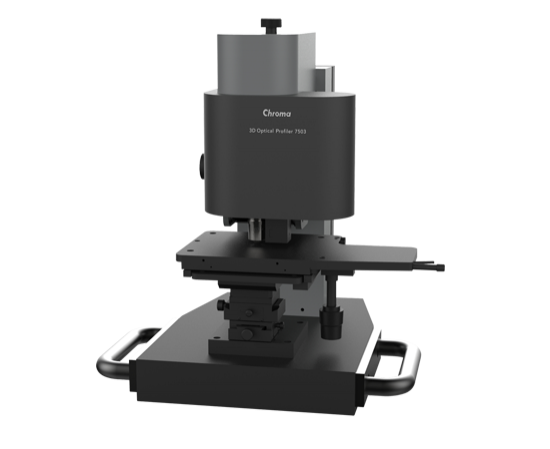

Traditional measurement utilizes different tools and equipment to conduct random inspections manually. These methods are generally time-consuming and complicated for data collection. Chroma now offers an innovative automated optical test system designed specifically for multi-dimensional measurement.

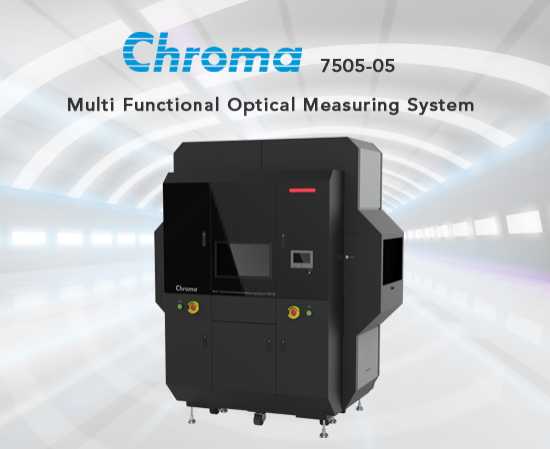

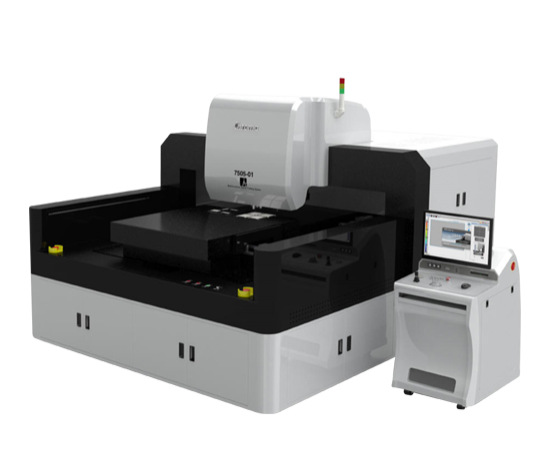

Chroma 7505-05 multi-functional optical measuring system is designed for the automatic testing of optical image quality for smartphone metal cases, batteries, cover glasses and other products. This system architecture utilizes high and ultra-high resolution cameras as well as laser scanners to capture images. A concept similar to the reverse engineering theory is applied to the measurement using 2D and 3D probe to provide full data analysis.

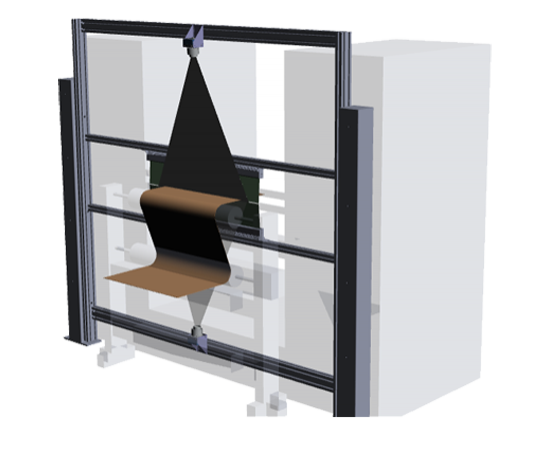

Equipped with a newly patented high-speed flow channel measurement technology, this system acquires multi-dimensional measurement of the unit under test by moving it through the conveying table from right to left in high speed.

The Chroma 7505-05 measuring system is integrated with a high efficiency optical master system software primarily for measuring dimensional range of the unit under test. User can set detection area with upper and lower limits. A measured dimension histogram that shows the quality of each test item, along with the SPC control chart, can be displayed if selected on the software main screen. This system also has a report storage function that saves test data of each device and provides immediate data collection, statistics, as well as process monitoring information. The advantage of having such real-time process control ability allows early detection of potential problems while improving process efficiency and competitiveness.

Combining both 2D and 3D high-speed real-time measurement capabilities, the Chroma’s 7505-05 multi- functional optical measuring system will provide a valuable and effective metrology tool for your production environment.