Description

Magnetic component’s heat comes from copper loss and iron loss. The copper loss caused by flowing current and wire resistance. The iron loss including Hysteresis Loss and Eddy Current Loss, mainly comes out from AC current. The inductance of magnetic component will drop unexpectedly if the temperature gets too high.

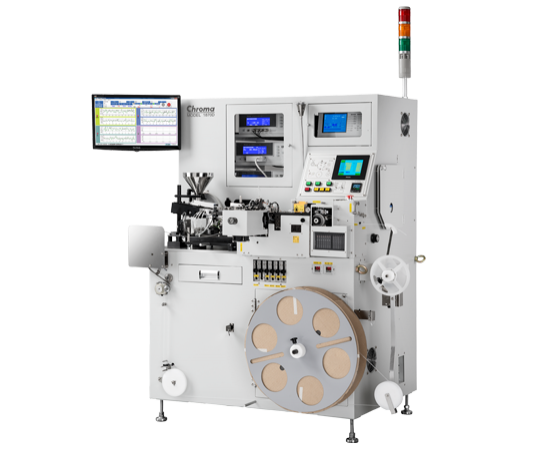

Chroma 1810 is a test system for detecting the power loss of magnetic component. It provides DC current and AC voltage to the component, and it has a temperature sensor detects the temperature on component. The analysis reports will record the result in computer by using test program. These statistic analysis reports are important for researching and quality control department.