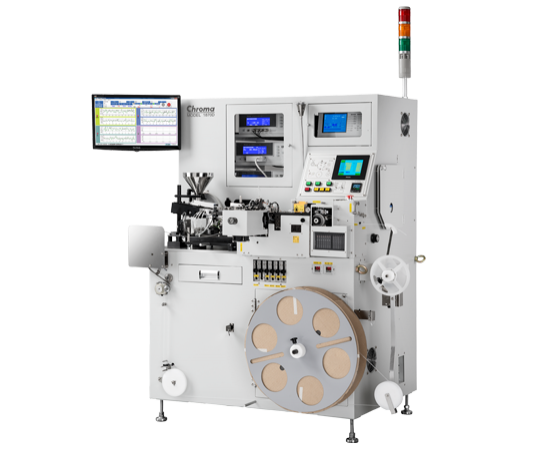

Description

The Chroma 1871 is an automatic test system specifically designed for chip inductors in testing layer short for mass production applications. This system inherits all judgment functions from the Chroma 19301A impulse winding tester including Area, Laplacian, and two new test functions -ΔPeak Ratio and ΔResonant Area.

As miniature inductors are widely used in the electronic products today, mass production of power inductors is necessary. The production capacity of Chroma 1871 is up to 1,500ppm, which can satisfy the quantity demanded. It uses 5 layer short test stations to conduct the testing at one time for fast production. Alternatively, it can select 2 layer short test stations for R&D or QA unit use to run in a cost-effective way.

The Chroma 1871 uses a circular vibrating plate that carries thin products at high speed for feeding. The circular vibrating plate uses a guide rail design, fiber detection and blow hole to determine the feed direction. This is fast and space saving when compared to traditional linear reciprocating mechanical feeders.

When moving inductors for testing, the traditional reciprocating or turret-type mechanical s t ructure uses a nozzle to attract the inductor for movement, and the product often drops due to inertial effects or inaccurate positioning making it unable to test. The Chroma 1871 uses an index disc design for testing, so that the equipment is within a closed architecture that can eliminate dropped inductors during highspeed movement. It is faster and more stable when compared to the traditional mechanical structure.

Chroma ATE Inc. not only specializes in elect ronic test ing technology but also masters in fixture design for automated test equipment. The test socket used by the Chroma 1871 is a four-wire measurement design that is more accurate and stable than common automatic test equipment. The chip design applied to the connection of the test socket and inductor is easier to contact and has longer product life compared to a probe in use.

The Chroma 1871 has exclusive software for monitoring test status during production in real time, and saving the collected test data for each inductor. Real-time monitoring functions can benefit the production unit by reducing the production risk during manufacturing and cut down unnecessary working hours. The data collection function is favorable to R&D and QA units for product analysis and quality control. The software can perform data analysis to improve the product quality and increase profit.