Description

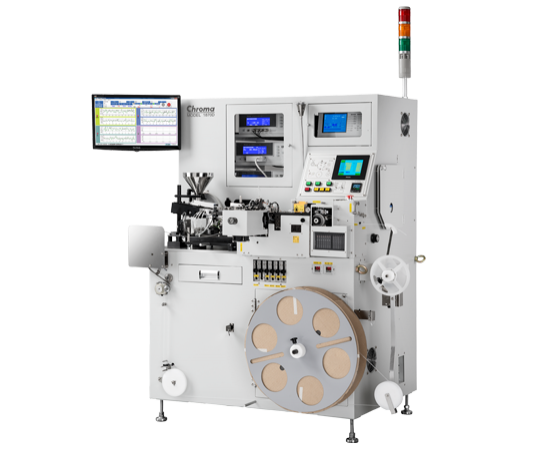

In recent years, as components become more complicated and multi-channel along with other complex problems, the cost of tests has skyrocketed for manufacturers. Chroma 8800 component automatic test system (ATS) is developed to effectively help manufacturers reduce the test cost and product risk. This system is able to complete all measurements and tests in one single test program. This powerful feature save time and reduce human operation errors that decrease the enterprise risk due to improper tests. The employment of open architecture software provides users a flexible, powerful and costeffective automated test system that is deemed the best solution for component tests.

Chroma 8800 component automatic test system integrates different test instruments in the system based on test requirements. The open architecture software offers corresponding solutions by various test programs and products that give customers highly flexible test combinations. In addition, user expandable test items are provided for editing if new requirements arise.

This automatic test system uses a unique test command optimization technology to prevent the repetitive control commands from sending to the system hardware devices. This technology improves the system test speed dramatically. Users create new test items based on their requirements using the test item editor. The users can expand the test items as needed.

The system’s integrated statistical and management functions generate various test statistical repor ts and per forming system administration. Statistical repor ts are very important in factories for research and design (R/D) evaluation, quality assurance (QA) verification and production tests. Chroma 8800’s Window 2000/XP environments provide test engineers with a dedicated components automatic test system in a familiar Windows environment and allows accesses to resources provided by Windows.

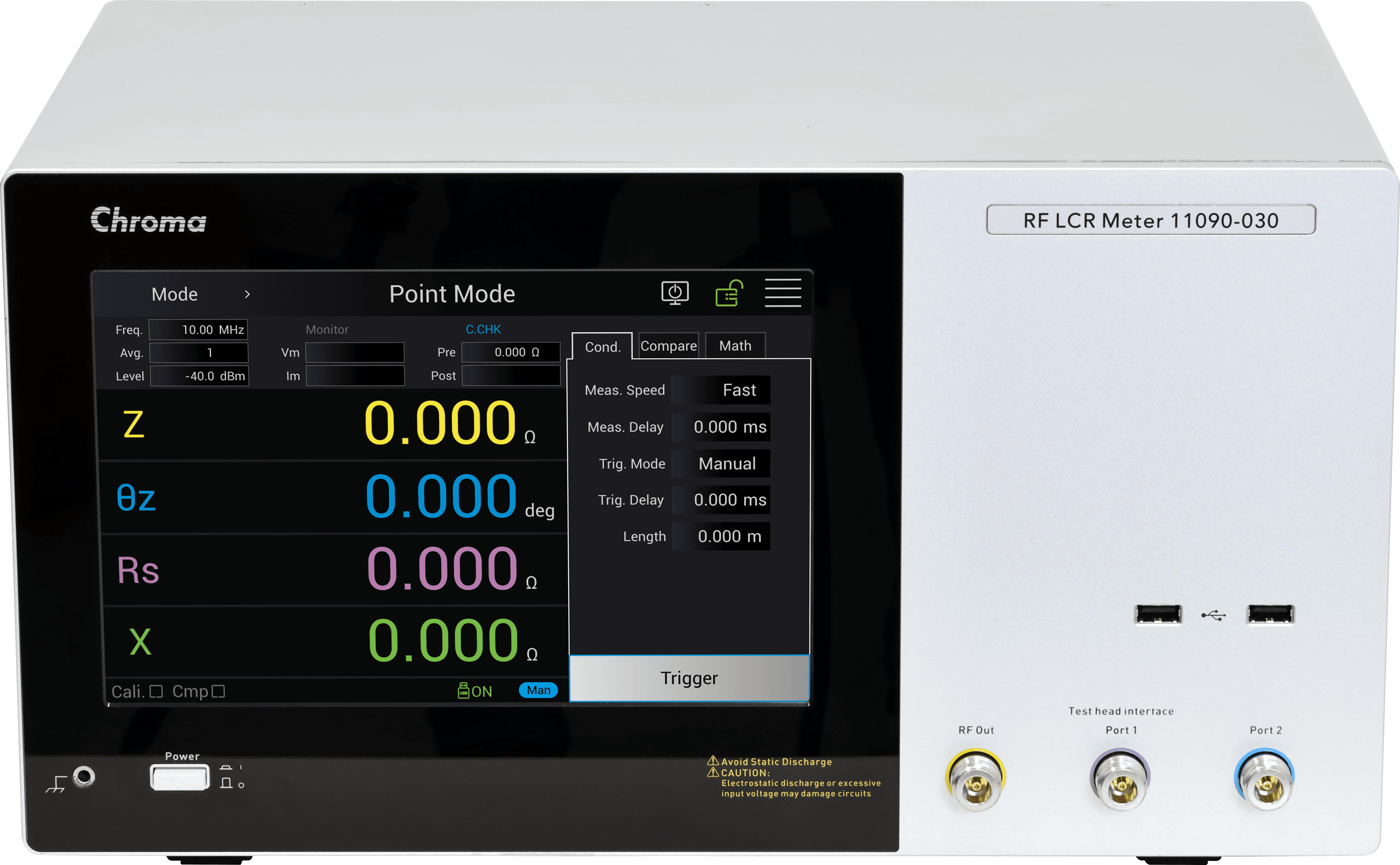

Chroma 8800 component automatic test system can combine different testers and hardware according to the test requirements. For instance, Chroma 13001 performs multi-channel scan test for inductance, capacitance and resistance along with turn ration (if applicable) measurements when combining with the LCR Meters like Chroma 3302/3252/11022/11025. The 8800 can do IR test as well as leakage inductance measurement that is designed specially for short-circuit when combining with Chroma 11200 CLC/IR Meter. Chroma 13001 Component Test Scanner supports up to 320 channels per unit when 8 optional A1130007 40-channel scan modules are installed. Up to 8 slaves of Chroma 13001 can be expanded externally for an 8800 component ATS and up to 2880 channels (1 master plus 8 slaves) can be tested to fulfill the requirements for multi-channel tests.