Description

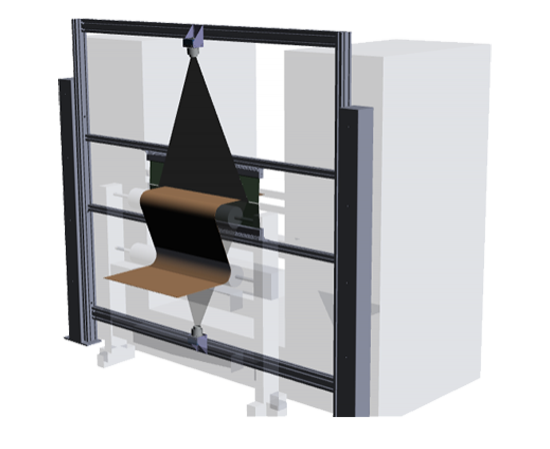

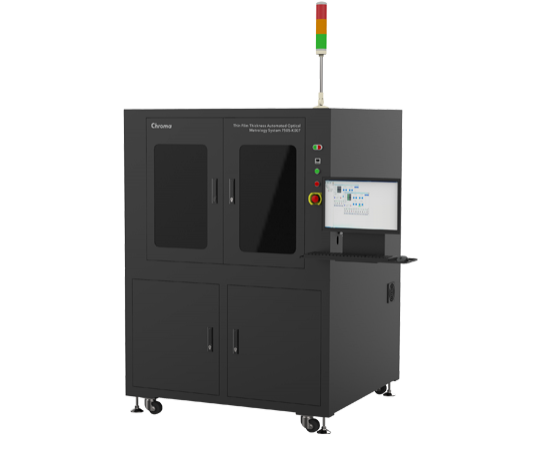

The Chroma 7505-K009 Inline Printing Quality Automated Optical Inspection System equipped with high-resolution camera can perform 2D defect detection that is suitable for Roll to Roll processing and on-line quality control. Both front and rear sides can be inspected at the same time. The defect test items include exposed substrate, fisheye, wrinkles, spacers, spacer separation, spacing length, misalignment, and unevenness on both sides, etc. Besides high throughput, the system also offers storage function to save the data detected for operators to analyze easily.